Electrical enclosures protect your electrical devices from dirt, particles, and moisture, which would do severe harm otherwise. The resulting heat generated by this equipment’s operation will cause degradation as the temperature inside the enclosure will continue to increase without any cooling.

Selecting the right cooling solution for your electrical enclosure can be complicated and confusing. Yet, operating all your equipment within specified temperature ranges is critical to optimal conditions. There are many vital factors to help you choose the right enclosure cooling solution for your specific needs.

Which Key Factors Should I Consider For Cooling?

Step 1: Establish Your Desired Temperature

The sensitive components housed inside your enclosure must be kept under a maximum temperature to function safely, perform reliably, and maximize their lifespans.

First, reference the manufacturers’ specifications of all components inside the enclosure to find the recommended operating temperatures for each of them. Next, choose the lowest of these temperatures to target.

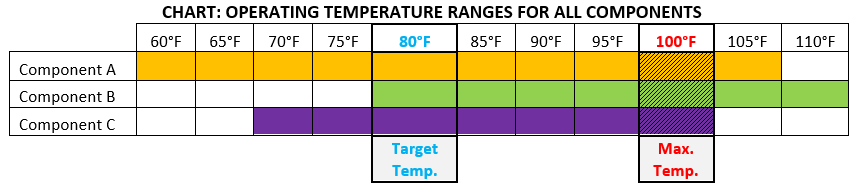

For example, if a manufacturer’s manual of the components inside an enclosure states:

- Component A can operate at 60 – 105°F

- Component B can operate at 80 – 110°F

- Component C can operate at 70 – 100°F

It is best practice to design your cooling system for a temperature 20°F below your equipment’s maximum allowable temperature.

Then, the interior temperature of your enclosure needs to be at or slightly under 80°F for all components to function efficiently.

After figuring out the desired temperature, you will want to design your cooling system to remove excess heat and allow the interior space to remain as close to your desired temperature as possible.

Step 2: Know Your Enclosure Dimensions

Knowing the dimensions of your enclosure allows you to understand the total volume you will be cooling and possible heat transfers by how much surface area is exposed.

Step 3: Determine Ambient Temperature and Environmental Heat Sources

External heat loads will impact the cooling capacity that you need. When calculating the maximum ambient temperature in your environment, you must consider external heat sources, e.g., nearby industrial manufacturing equipment, extreme outdoor temperatures, and solar heat gain due to lack of shade.

Then, examine the air flow conditions. Whether your location is well or poorly ventilated will also impact calculations.

Step 4: Estimate Your Internal Heat Load

Internal heat load refers to the heat generated by the components inside the enclosure. Refer to the manufacturers’ specifications to calculate the thermal losses from your equipment inside the electrical enclosure. If your enclosure has insulation, this will impact heat transfers as well.

Step 5: Calculate the Total Heat Load

To calculate the total heat load, add your internal and external sources of heat, which will provide the total amount of excess heat that your cooling system needs to remove and, by extension, the required cooling capacity of your system.

What If I Choose the Incorrect Size?

An Underpowered Unit

Units that are underpowered for your application will constantly run, which will increase operating expenses, not properly cool your enclosure, possibly damaging sensitive equipment, and have a shorter life span due to the increased load on the unit.

An Overpowered Unit

Overpowered units for your application will be less cost-efficient as a solution, run less efficiently, increase operating expenses, lead to more temperature variability, and shorten the life of your unit by frequently cycling.

How Do I Use the BTU Calculator?

ISC Sales has a custom BTU Calculator available for anyone to use. This BTU calculator considers various factors relevant to keeping the components in your enclosure safe from the elements. The below instructions will walk you through the process of using our BTU Calculator.

Instructions

- After adding your email and project name to their respective fields, select your relevant unit system – English or Metric.

- Select the type of calculator you need. Hint: “Air Conditioners” is perfect if the enclosure’s internal temperature must be lower than the ambient temperature, and “A2A Heat Exchangers” or “Filter Fans” are great for those applications where the desired temperature for the enclosure is equal to ambient temperature.

- Enter the dimensions of your electrical enclosure (accuracy is vital to size your cooling unit correctly).

- Determining the correct “Desired Enclosure Temperature” is based on the operating guidelines for the components within your electrical enclosure. Check your owner’s manual for the optimum temperature.

- Ambient temperature refers to the temperature in the immediate surroundings of the enclosure’s location.

- Heat load is calculated by adding up the maximum heat output for each electrical component within your enclosure, measured in watts. This information can typically be found on the label of each electrical product or obtained from the product manufacturer.

- Enclosure material depends on your specific application, e.g., hazardous environments often require stainless steel.

- Enclosures with a darker color will have more heat transfer when in direct sunlight.

- Insulation shields the interior from exterior temperature very well; however, most enclosures are uninsulated.

- The unit location and airflow conditions of your electrical enclosure can influence the cooling requirements greatly. An enclosure in direct sunlight will have a higher BTUH cooling requirement or one with no airflow.

- Once you have finished the form, select “calculate” to have our custom BTUH calculator help you pick the best enclosure cooling solution for your application.

What If I’m Still Unsure?

Once you have your cooling requirement, you can find the perfect solution for enclosure cooling on our website! Or, if you have more questions, please contact ISC Sales to speak with an enclosure cooling specialist. We will work with you to select the best enclosure cooling solution for your specific application.