With so many available options for materials and types of enclosures, it makes it difficult to decide which electrical enclosure will work best for your application. To help you make this decision we have listed 10 Facts You Must Know.

1. Environment

Where your enclosure will be located and what it will be exposed to are the most important considerations to be made while determining which enclosure type will work best for you and your application. All enclosures have different needs based on its location and what could harm your equipment.

An electrical cabinet installed inside a factory may come into contact with chemicals, corrosive materials or it may be positioned near very hot equipment, such as furnaces or ovens that could also heat up your electrical components.

An outdoor enclosure is vulnerable to Mother Nature; heat radiation from the sun, strong winds and heavy rain during thunderstorms, high summer temperatures and maybe even snow.

Thankfully, once you have pinpointed the risks to your equipment you can use NEMA ratings as a guide to determine which type of cabinet will withstand the environment it’s placed in.

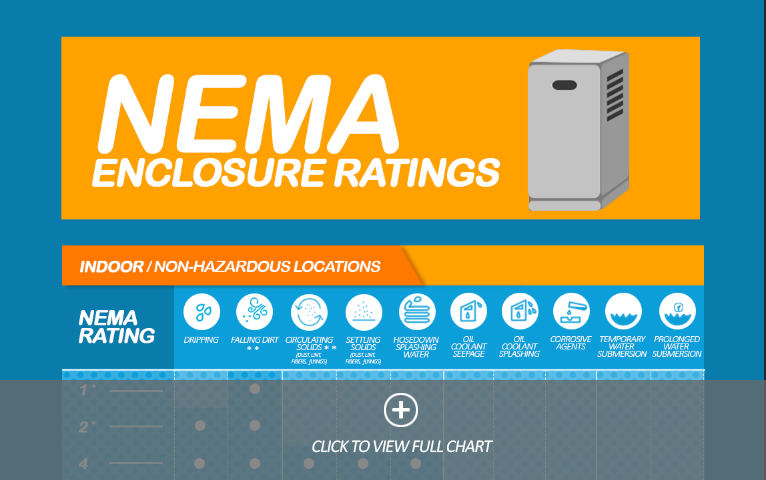

2. NEMA Rating

According to their website, “The National Electrical Manufacturer’s Association (NEMA) provides a forum for the development of technical standards that are in the best interests of the industry and users.”

NEMA ratings standardize product specifications while establishing performance criteria, or in other words, their ratings make sure that consumers are buying the correct enclosure to safely house their electrical components based on its environment and the type of equipment inside.

Depending on which material the enclosure is constructed out of, it may only qualify for certain NEMA ratings.

3. Durability and Impact Resistance

Some materials are stronger than others when it comes to durability and impact resistance. It is important to consider whether or not your enclosure is in danger of being run into by a vehicle or hit by falling heavy equipment. The resilience of your cabinet may save you from downtime due to an accident in the future.

Another thing to consider is security. Is your enclosure at risk of being broken into? Is there expensive equipment inside that needs protection? A sturdier material will make intrusion more difficult or even impossible for burglars.

4. Modifications

Some enclosures are easily modified to fit the specific needs of consumers or OEMs (Original Equipment Manufacturers). If modifications must be made to make the enclosure a perfect fit for your application, be sure you’re purchasing an enclosure that is constructed with a material that allows for easy fitting and cutting of holes for wiring components.

If standard enclosures will not suit your needs, it is possible to have your cabinet custom made to fit your exact specifications.

Read Enough But Still Have Doubts?

Read Enough But Still Have Doubts?

5. Thermal Management

If your electrical cabinet will be exposed to high heat loads, it may benefit from an enclosure cooler. It goes without saying, high heat loads mean trouble for electrical equipment. Too much heat can cause system failures and premature equipment break down.

There are many versatile options perfect for any application. To learn more about enclosure coolers, “What is Enclosure Cooling? (A Colossal Guide to Becoming an Expert),” goes into great detail on how to determine which cooler will work best for your application, as well as, how the different systems work.

Designing your enclosure with cooling in mind will save you from costs down the road if you allow for easy modification.

6. Enclosure Size

The size of your enclosure will impact which type of material will work best. Some materials, like polycarbonate, are typically only used for smaller enclosures. Steel is a popular option for large enclosures.

7. Aesthetics

Some enclosures will be hidden, out of sight from employees and the general public and how they look isn’t a concern. Then again, some electrical cabinets require a little more finesse to be more appealing for building design and aesthetics.

Some materials can be painted any color, while some have shiny, reflective surfaces making them more appealing to the eye than other options. Certain enclosures allow for the addition of clear windows, making it possible to view electrical components without having to open any doors.

8. Weight

Many cabinets are required to be mounted on walls for best application use. Bulky and heavy materials will make this more difficult.

For example, if something made from polycarbonate weighs one pound, it will be the equivalent of one and a half pounds if made from fiberglass, two pounds if made from aluminum or six and a half pounds if made out of steel.

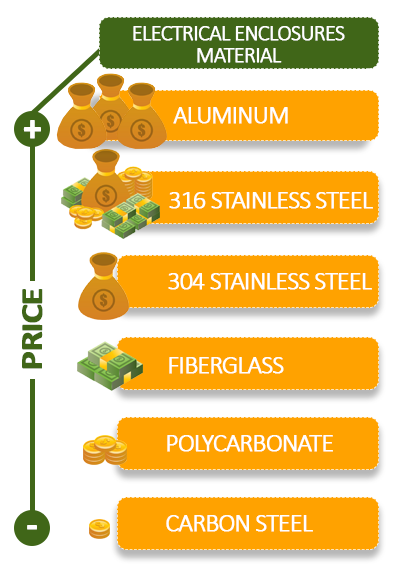

9. Budget

Many materials will meet the requirements you need for your electrical cabinet, but the price may also influence your decision. Some materials are affordable when in a smaller size, but when needed for large enclosures can become quite expensive. The price range per material is usually the following:

For any size or budget, there will be an enclosure that will work well for you and your application.

10. Materials to Choose From

Polycarbonate (Plastic) Enclosures

Polycarbonate is a fancy word for plastic. It is the lightest option for enclosure material.

Polycarbonate is the easiest material to modify, holes can easily be drilled to accommodate for on-site modification. It will not deteriorate due to UV exposure. Plus, it is also resistant to corrosion and some acidic environments. However, it is highly sensitive to abrasive cleaners.

Plastic is non-conductive and non-magnetic, making it ideal for use with sensitive equipment that is affected by metal. Plastic will not block radio waves which makes it perfect for enclosures that house Wi-Fi emitting components.

These enclosures have a clean look and include the option for transparent panels. The optional windows allow personnel to view electrical equipment without having to open any doors to the enclosure, an advantage for components in particularly harsh environments where even limited exposure could prove disastrous.

Pros:

- Easy to Modify

- Cost Effective

- Lightest weight option

- Non-conductive/ non-magnetic

- Will not block radio waves

Cons:

- Size Limitations

- Sensitive to abrasive cleaners

NEMA Ratings – 1, 2, 3, 3R, 3S, 4, 4X, 5, 12, 13, 6P, 12, 13 & Marine Use

Aluminum Enclosures

Aluminum is amongst the oldest type of enclosures. It is a readily available material that is lighter than its cousin, steel, which is also used in enclosure construction.

Aluminum is sturdy, capable of withstanding high impact and has high malleable strength, making it great for irregular shapes or designs. Aluminum enclosures are easier to modify than other metals.

Aluminum performs well in harsh environments, the alloys are naturally resistant to corrosion and rust. It is also resistant to UV light. However, it is thermally conductive and will trap heat. This may require powder coating to help control the heat load.

Aluminum is one of the least electrically conductive metals and has some the highest electrical resistance. In most instances, aluminum is non-reactive to magnetic force. These qualities make it excellent for enclosures that need a shield against electromagnetic frequency (EMF) and radio frequency interference (RFI).

Aluminum will not swell or deform and has a consistent quality finish. It is easy to paint or coat and the scrap is recyclable and valuable.

Pros:

- Non-sparking/ Non-magnetic

- Can be made in a wide range of sizes

- Consistent quality finish

Cons:

- Sharp edges if modified

- Thermally Conductive

NEMA Ratings – 1, 4, 4x, 12, 13

Stainless Steel Enclosures and Carbon Steel

Steel is the standard material choice for many industries and it’s easy to see why. It is highly durable and is corrosion resistant, moisture resistant and chemical resistant. It is the strongest of the material options, able to withstand the greatest amount of impact while maintaining aesthetics.

Carbon steel and stainless steel are both used for enclosure construction.

As the name states, carbon steel is steel that has been bonded with carbon. People also commonly call it “mild” or “wrought” steel. It can easily be painted or powder coated. A lighter color can make enclosure’s internal temperatures up to 10 degrees Fahrenheit cooler than unpainted cabinets in the same environment.

Stainless steel is steel mixed with chromium and nickel. The addition of nickel makes stainless steel especially temperature tolerant. This means it will maintain material integrity even at very high and very low temperatures.

Stainless steel is non-porous, making it bacterial and fungal resistant. This type of steel is particularly suited for food manufacturing and medical applications.

Pros:

- Corrosion resistant

- Easy to clean

- Chemical and water resistant

- Impact resistant, can withstand extreme pressure

Cons:

- Most difficult material to modify

- Not scratch resistant

NEMA Ratings – 3R, 4, 12, 13

Custom Enclosures

Custom enclosures offer excellent quality and are built exactly how you want it.

ISC offers custom electrical enclosure solutions for a wide range of industrial and commercial applications. The units are constructed using the finest aluminum, stainless steel or domestic carbon steel available.

Stainless steel enclosures come with a brushed finish, while all carbon steel products have a powder coating finish.

All custom-made models are UL, cUL and CSA approved and adhere to both NEMA and the Joint Industrial Council standards. Custom designs are engineered and manufactured with the support of CAD/CAM technology along with a team of experienced design engineers.

Cost and lead time are the only negatives.

Optional Enclosure Accessories:

- Louvers

- Swing out panels

- Window kits

- Dead fronts

- Sun shields

- Drip shields

- Custom Cutouts

- Penetrations

- Disconnects

Still unsure of which electrical enclosure will fit your needs?

Needs vary so much from application to application it is hard to determine what will work best.

But you’re in luck! The staff at ISC Sales is very knowledgeable, able to answer any of your questions and will ensure that you get the most efficient product for your business. Contact us today and have the electrical cabinet that’s perfect for you tomorrow.

Call ISC Sales today at 877.602.0010 to get a free quote or to ask about our lineup of industrial equipment. You can also request a quote online, HERE.