Unless you are lucky enough to live and work in a tropical location, it’s a pretty safe bet that your application will require additional heating. The enclosures that house your delicate and essential electrical equipment need a little extra help staying warm during frigid winter months.

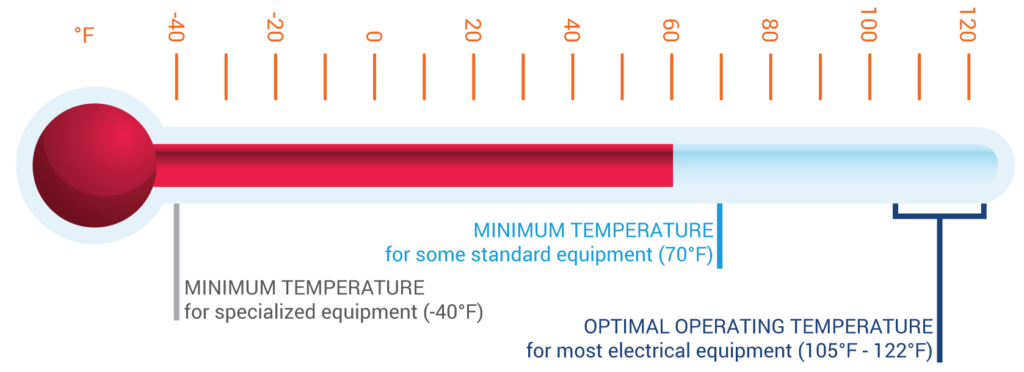

Temperatures as low as negative 60 degrees Fahrenheit are recorded on a regular basis. In fact, most states located in the United States reach lows well below manufacturer’s optimal temperature levels for electrical equipment.

When the temperature inside the enclosure increases or decreases it can negatively affect the electrical components within.

The optimal operating temperature for most electrical equipment lies between 105 and 122 degrees Fahrenheit, with minimums ranging from 70 degrees for some standard equipment to 40 degrees below zero for specialized equipment.

Temperatures can easily fluctuate anywhere from 10 to 30 degrees in a single day and even typically warm climates like Nevada and Florida still have freezing temperatures in their forecasts.

Weather is unpredictable.

It’s better to be prepared than be caught unprotected, leaving your application vulnerable to downtime due to an electrical system failure.

1. Things that Influence Temperature

2. Effects of Cold Weather on Electrical Equipment and Enclosures

3. Why Heat an Enclosure?

4. Benefits of Enclosure Heating

5. Types of Enclosure Heaters

6. What to Know to Get the Right Enclosure Heater

1. Things That Influence Temperature

Ambient Air Temperature |

Sunlight |

Wind |

Humidity |

Ambient Air Temperature: This one comes as no shocker. If it is cold then the enclosure itself and the components inside will be similar to that temperature. Ambient temperature is just a fancy term for saying room temperature, or the temperature of the surrounding environment.

Electronics, just like you, will get cold or hot depending on the surrounding climate. They require additional help to maintain comfortable operating temperatures, such as heaters and air conditioning, just like we do.

Sunlight: While sunlight does nothing to increase the temperatures we feel, heat radiation emitted from the sun can help warm objects like pavement, sand, grass and your enclosure.

The lack of sunlight can mean colder temperatures. Winter days are shorter and mean fewer hours of daylight, which means less opportunity for enclosures to get heat from the sun.

According to a 2002 San Jose University study, temperatures in enclosed cars with a basic gray interior rise approximately 19 degrees F in 10 minutes’ time; 29 degrees in 20 minutes’ time; 34 degrees in half an hour; 43 degrees in 1 hour; and 50-55 degrees over a period of 2-4 hours when left in sunlight.

This gives you a pretty good idea on how much sunlight can impact the temperatures within your enclosure.

Wind: Wind chill is when the temperature of an object decreases by the passing flow of lower-temperature air. This can affect enclosure temperatures by disrupting the boundary layer that exists around objects that are warmed by convection.

By disrupting the boundary layer, the wind can replace the warm air against the surface with cooler air. This can increase the rate of heat loss, which reduces the ambient temperatures surrounding the object.

Wind can also make it harder for spaces to retain heat if they are not properly sealed off. Ventilated areas cannot hold heat as well as insulated and sealed areas.

Unsealed openings can also let in harmful water, snow and dust, which can all negatively impact how your electronics work.

Humidity: Humidity can have a huge effect on how much temperatures fluctuate. Death Valley California is the driest place in the United States, its humidity levels are well below the national average.

With its lack of humidity, it sees huge differences in temperature between day and night.

In September, Death Valley’s average high temperature is 107 degrees Fahrenheit and its average low is 76 degrees- a whopping 31-degree difference between day and night!

2. Effects of Cold Weather on Electrical Equipment and Enclosures

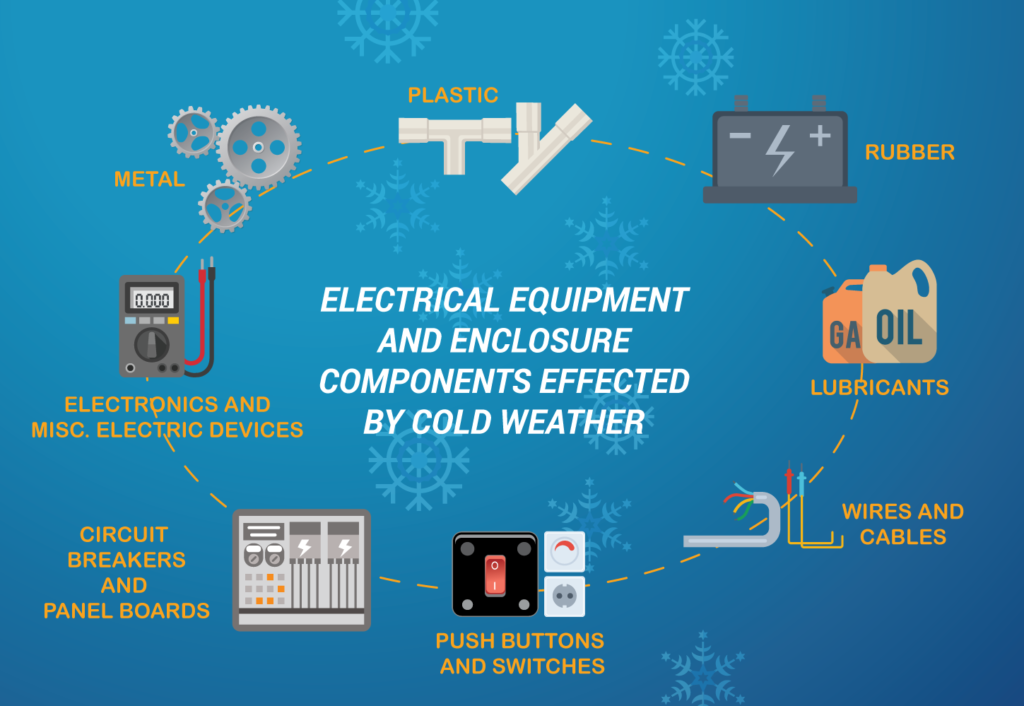

Electrical systems are comprised of thousands of components, all of which have specific operation temperatures and conditions in which they function at their best.

When temperatures drop to well below freezing, there are many effects on those components that can occur due to the bitter cold.

If enclosures are not heated properly to combat cold temperatures these are the things that can happen to your equipment:

- Metal:

Metal can lose ductility, becoming more brittle, affecting its ability to withstand impact and explosive pressures. This can reduce the reliability of metal enclosures and compromise their integrity to protect against explosions. - Plastics:

Plastics, when exposed cold temperatures, can also become brittle. Some plastics can reach this vulnerable state at 32 degrees. Plastics can become glass-like if they are exposed to low enough temperatures. Plastics can also lose their ductility, but at a much lower rate than metals. Another concern for plastic is that it can buildup static electricity in cold weather because of a reduction of humidity. This is especially dangerous in hazardous location enclosures. Static can also cause sensitive electrical equipment to malfunction and give off incorrect readings. - Rubber:

Rubber can become stiff and lose flexibility. This results in inadequate sealing and the loss of tightness of the grips on glands. - Lubricants:

Lubricants can freeze and cause a malfunction. Many components require lubricants to work properly and if they become frozen they no longer serve their purpose and can lead to problems with the equipment. - Wires and Cables:

The insulation inside of wires and cables can become hard and brittle. Hard and brittle wires and cables can affect the conductibility and can cause breakage. - Push Buttons and Switches:

Push buttons can become stiff and difficult to operate. If the grease that allows for easy operation freezes and turns viscous it will prevent proper operation. Other types of lubrication can absorb moisture and then freeze.It is important to know which lubricants you are using in your application and their temperature limits. In hazardous locations, cold weather can result in a nonoperational emergency stop device pushbutton.

Differential expansion also needs to be taken into account if different materials used on close fitting joints of flame paths. Flame paths must remain open to allow for proper explosion prevention.

- Circuit Breakers and Panel Boards:

Even breakers designed for low temperatures are generally only designed for lows of 5 to 15 degrees below zero.When it is cold, the standard grease used during the production of circuit breakers and panelboards could freeze, preventing operation of the circuit breaker.

- Electronics and Miscellaneous Electric Device:

As temperatures drop, changes can occur in the resistance and capacitance resulting in timing changes on integrated circuits, waveform changes and other electrical properties.Various materials used in making and mounting the components can be greatly affected by differential expansion, contraction and thermal cycling effects.

If you live in an area where it’s possible or probable that the environment will remain below your component’s optimal operating temperatures, it is important to choose equipment that can withstand the low ambient temperatures or have a way to raise temperatures, such as enclosure heaters.

3. Why Heat an Enclosure?

SAFETY AND FUNCTION

Maintaining safety and function is the main objective for heating systems within electrical cabinets. Your whole production process depends on all equipment working properly; with even one component down it can have disastrous effects on productivity.

In extremely frigid environments safety and functionality can be compromised. Low temperatures can have a huge effect on how well the electrical components work.

Using an enclosure heater counteracts the negative effects of cold weather on these components. It keeps equipment working at its best while maintaining their integrity, which is especially important for enclosures that are located in hazardous locations.

4. Benefits of Enclosure Heating

Removes Moisture and Prevents Condensation

The negative effects of moisture and corrosion can be held at bay if the relative air humidity within the enclosure remains below 60 percent. Once the humidity reaches 65 percent, the chances of problems associated with moisture and corrosion increase.

A constant temperature within the enclosure will prevent any condensation from forming. This is because it eliminates temperature fluctuations and this makes it less likely that moisture will collect.

Prevents Equipment Failure and Downtime

By keeping temperatures consistent within the enclosure, it effectively lengthens the life of electrical equipment and prevents the chance of system failure. It ensures the systems won’t overwork.

They keep condensation from forming which can harm sensitive electronics and cause them to stop working.

Keeps Equipment Working at Optimal Levels

Manufacturers have the optimal working temperatures listed for all electrical elements. Keeping enclosures within in this optimal temperature range keeps the electrical equipment functioning.

If it remains in the sweet spot, it can prolong the life of the components by preventing overworking.

Prevents Corrosion

Moisture is the natural enemy of electrical equipment. When it is combined with aggressive gases and dust, it causes atmospheric corrosion and this can lead to the failure of important components such as circuit breakers, busbars, relays, integrated circuit boards and transformers.

5. Types of Enclosure Heaters

There are many types of heaters, ranging in wattage, mount capability and construction material available from ISC Sales. No matter how complex your production process is ISC Sales has an enclosure heater to meet your specific needs.

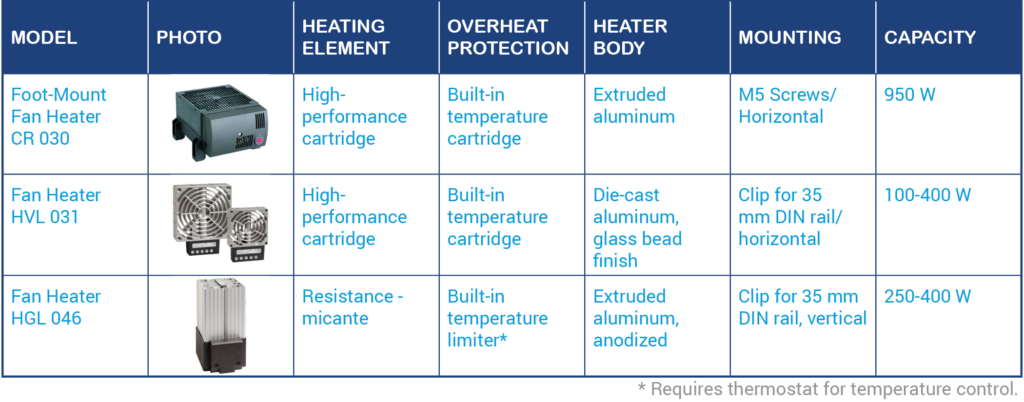

Fan Heaters

Fan heaters work simply. They run a current of electricity through a heating element, like a high-performance cartridge, which creates heat.

Air is then drawn in over the heating element using a fan which causes air to become warmed rapidly. The air is then propelled out into the enclosure.

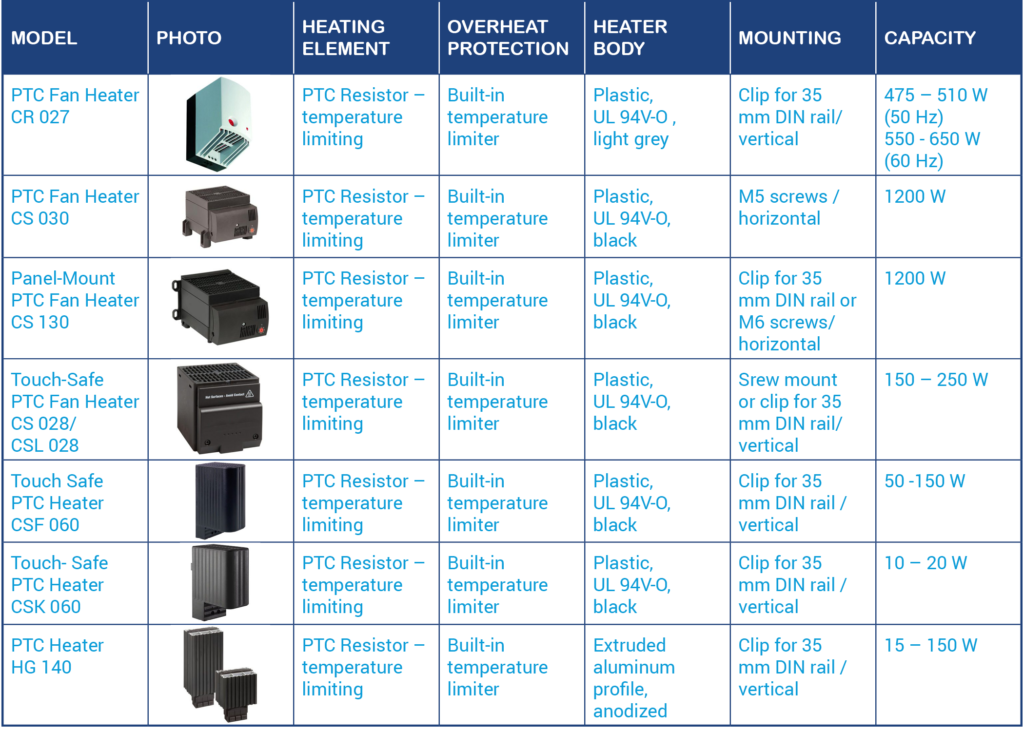

PTC Heaters

Positive temperature coefficient (PTC) heaters do not use traditional heating elements that are used in fan heaters, they use specialized conductive materials. As the temperatures rise, the electrical resistance of the materials also increases, this limits the current flow.

In other words, the material used lets the electrical currents pass when the enclosure is cold but as it begins to get warmer it starts to limit the current’s flow.

This means that they are self-limiting and will not overheat, because the heating power adjusts to the ambient temperature. Fans may be added to make the heating occur faster.

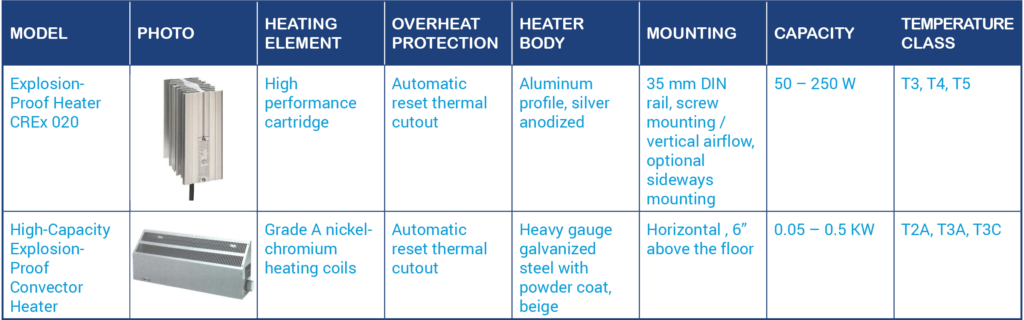

Explosion Proof Heaters

Explosion proof heaters use convection to heat enclosures. The heaters use air convection currents to circulate air through the heater body and across the heating element, causing the air to heat up, increasing its volume, making it rise.

This process continues until all of the air within the enclosure is heated. The result is a convection current which continuously circulates the heated air, keeping the enclosure at the right temperature.

Explosion proof heaters are the only heaters rated for use in hazardous locations. Be sure you are purchasing the correct heater according to your application’s specific requirements.

6. What to Know to Get the Right Enclosure Heater

1. What wattage do you need?

Different models and types of heaters will have different wattages. Know what your wattage requirement is to find the correct heater for your application.

2. What type of heater do you need?

If your enclosure is located in a hazardous location it will have specific certifications in order to meet the standards for safe function and to effectively prevent explosions.

Some heater types are limited by their mount orientation or construction material. It is good to have an idea of your space restrictions or if any materials won’t be compatible in the enclosure.

3. How will you control the enclosure’s temperatures?

Many enclosure heaters come equipped with their own heat regulation system or thermostat, but some will require the addition of a temperature controller. Be sure you know how you can set the limits to keep the heat right where you need it.

Still have questions on enclosure heating products?

Needs vary so much from application to application it is hard to determine what will work best.

But you’re in luck! The staff at ISC Sales is very knowledgeable, able to answer any of your questions and will ensure that you get the perfect heating application. Contact us today to get started!

Call ISC Sales today at 972.694.4291 to get a free quote or to ask about our lineup of industrial equipment. You can also request a quote online, HERE.