Whether you know it or not, you’re probably familiar with dew point.

The condensation that forms on your cold glass of water, the fluffy clouds in the sky, the water that forms on grass overnight, and the water that collects on windows on cold winter days are all excellent examples of dew point in action.

In this article, we will explore dew point as it relates to compressed air systems.

1. Compressed Air Dew Point

2. What Are the Differences Between Atmospheric Dew Point, Pressure Dew Point and Frost Point?

3. What Is the Effect of Pressure on Dew Point?

4. Why Is Dew Point Important for Compressed Air Systems?

5. What Is the Typical Range of Dew Point Temperatures Found in Compressed Air?

6. What Are the Standards for the Quality of Compressed Air?

7. How Is Dew Point in Compressed Air Measured?

8. Final Recommendations

1. Compressed Air Dew Point

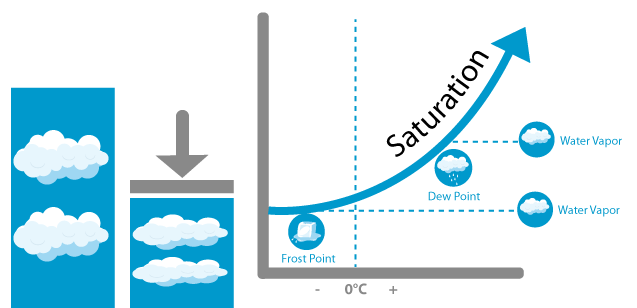

Dew point (DP) is the temperature at which your compressed air becomes fully saturated so that it cannot hold any more water vapor. This saturation causes condensation. In other words, dew point is the temperature when water vapor becomes liquid.

When the air temperature equals the dew point temperature, the air is at saturation point – when we begin to see water droplets forming. At this temperature, water becomes visible. You can see the condensation when you have a cold drink because the temperature of the glass is lower than the dew point of the air.

Note: Pressure changes affect DP, NOT temperature changes. As pressure rises, the DP increases. When pressure decreases, DP temperature also decreases.

2. What Are the Differences Between Atmospheric Dew Point, Pressure Dew Point and Frost Point?

Atmospheric Dew Point: This is the point that occurs naturally when the temperature and saturation point/dew point are the same and relative humidity is at 100 percent. Pilots and meteorologists use this to predict weather conditions.

Pressure Dew Point: Pressure DP is the temperature of gases at pressures higher than atmospheric pressure, like in a compressed air system. This is important because changing the pressure of a gas changes its saturation point.

Frost Point: Frost point is usually a temperature below 0 °C or 32 °F, at which point water vapor condenses into frost instead of into liquid water. Since it will be a different measurement than dew point below 0 °C, frost point is an important differentiation of dew point.

For instance, DP is usually about 4 °C lower than frost point at -40 °F. DP’s temperature is meaningful for ISO Standards, which we will cover later in this article.

3. What Is the Effect of Pressure on Dew Point?

DP is the most commonly used measurement for compressed air systems because as pressure rises the dew point temperature also rises. Our handy dandy chart above illustrates this fact.

So, what exactly does this correlation mean? If pressure increases, the DP temperature will rise and approach saturation. The amount of water vapor in the air has to be reduced so that the saturation point stays the same or even lowered.

If DP is higher, then more moisture is present in the air.

It is easier for liquid water to enter the compressed air system at this point because the gas can easily reach its saturation point. This is why air dryers are so commonly used with compressed air systems.

| Temperature

°F (°C) |

Saturation Vapor Pressure (mbar) |

| 68 (20) | 23.5 |

| 32 (0) | 6.1 |

| 14 (-10) | 2.8 |

| -4 (-20) | 1.3 |

| -40 (-40) | 0.2 |

As the pressure of a system decreases, the DP temperature becomes lower. The gas will become relatively dryer as the difference between DP and ambient temperature increases.

Therefore, we can conclude that drying the surrounding air effectively lowers DP temperatures.

4. Why Is Dew Point Important for Compressed Air Systems?

Why care about DP? Because water can damage industrial equipment and even ruin end products.

In particular, water can cause…

- Rust and increased wear of moving parts because it washes away important lubricants

- Paint that is applied to compressed air systems to change colors or not stick to products

- Problems with compressed air powered tools because of rust, scale, and clogged openings, including major damage and even costly downtime

- Faulty operations due to frozen control lines in cold weather

- False readings that are caused by corrosion on air or gas-operated instruments, which can lead to shutting down plant processes

Preventing water from entering your compressed air system will keep all those nasty things on that list from happening, and in the words of Martha Stewart, “It’s a good thing.”

5. What Is the Typical Range of Dew Point Temperatures Found in Compressed Air?

Dew points can range anywhere from ambient temperatures all the way down to -80 °C (-112 °F) below zero and sometimes even lower in some specialized applications.

Refrigerated air dryers use a heat exchanger to condense water out of the air stream, and they can usually produce air with a DP no lower than 5 °C (41 °F).

Desiccant air dryers absorb water vapor from the air stream and can drop DP significantly. They can get dew point to as low as -40 °F.

If you’d like more information on air dryers and how they work or help on deciding which style would work best for your application, check out “Compressed Air Dryers (The Easy Way to Eliminate Moisture!)”

6. What Are the Standards for the Quality of Compressed Air?

The International Standards Organization (ISO) published a set of standards under section 8573.1 which are air quality classes.

This standard sets the maximum limits for three categories of air quality:

- Particle size for any remaining particles

- Allowable DP temperature

- Remaining oil content

Classes of air are numbered one through six, and you can see from the table below the specifications for each class.

| Class | Particles | Dew point °C | Dew point °F | Oil mg/m^3 |

| 1 | 0.1 | -70 | -94 | 0.01 |

| 2 | 1 | -40 | -40 | 0.1 |

| 3 | 5 | -20 | -4 | 1 |

| 4 | 15 | 3 | 38 | 5 |

| 5 | 40 | 7 | 45 | >5 |

| 6 | – | 10 | 50 | – |

7. How Is Dew Point in Compressed Air Measured?

Air dryers can help lower DP temperatures and keep liquid water out of air compression systems. Even better, they are great at monitoring the air’s DP. However, if you want to be 100 percent sure, you can also use a hygrometer.

Most air dryers have built-in transmitters that ensure your equipment maintains the correct moisture levels within your compressed air system.

You should check and calibrate your system at least once a year or anytime you might be suspicious of the readings you are getting for your compressed air. Additionally, do remember that some processes, such as paint spraying or pharmaceutical manufacturing, may require certain dryness or purity levels.

Your DP monitor may be malfunctioning if it displays one value all the time, is always at the lowest possible value, changes rapidly or randomly, or displays unusually dry or wet DP values.

8. Final Recommendations

Dews

- Read your compressed air system’s safety manual and follow manufacturer guidelines!

- Prevent water from entering your compressed air system

- Check and calibrate your system at least once per year

- Install a hygrometer to ensure proper monitoring of dew point

- Check your compressor anytime you are suspicious of the readings you are getting

Dewn’ts

- Never install dew point sensors at the end of stubs or other dead-end pieces of pipe where there is no airflow

- Do not use nonmetallic tubing for your dew point sensor

- Do not exceed the recommended flow rate for your air compressor

Still Have Questions?

The compressed air experts at ISC Sales are happy to help! Just give us a call and we’ll be sure to get you the best product for your application.

We also have an entire blog article on air dryers and the effects of liquid water on compressed air systems and production processes called, “The Easiest Ways to Dry Compressed Air” Check it out!