Much like a water reservoir provides water during times of drought and stores water during the wet times, an air receiver tank maintains a steady supply of compressed air during peak demand and helps balance the supply of the compressor with the demand of your system so that you never run out of compressed air that is essential to your production process.

As an essential element to any compressed air system, compressed air receiver tanks serve as temporary storage, while also allowing your system to perform more efficiently.

They also serve to separate out particles and liquids and make the compressed air system easier to control.

1. How Air Receiver Tanks Can Save You Money

2. How Air Receivers Work

3. How to Properly Size Air Receiver Tanks

4. Products Offered by ISC Sales

5. Additional Helpful Products

1. How Air Receiver Tanks Can Save You Money

It dampens the pulsations from the discharge line of the reciprocating compressor, resulting in a steady flow of air in the system.

This makes for smooth delivery of air to the tool, or piece of equipment being used, and protects the hoses and other components from damage that can be caused by pressure spikes.

Protecting the components will help to lengthen their life and result in less money spent on repairs and replacement equipment.

Air tanks serve as a reservoir that can take care of sudden or unusually heavy demands for air that exceed the compressor’s designed capacity.

If the tank is correctly sized it can also allow for the use of a smaller compressor, which is especially helpful in applications that require higher airflow, then the compressor can continuously deliver but at low duty cycles.

It prevents the excessive cycling of a compressor. Less cycling means less wear and tear on equipment while reducing energy consumption.

This means less money is spent on power and replacement equipment.

Vessels can knock out solid dirt and particulate that could have passed through the compressor inlet filter or that was formed by compressor wear.

It divides out contaminants and oil carry-over from the compressor oil that might get into the compressor discharge and cause problems.

This means a longer life for equipment which will result in fewer repairs, maintenance, and downtime.

Air receivers help to cool the compressed air and separate out the moisture that results from air compression.

Removing this moisture is essential for making sure components run as long as possible and prevents any condensation from forming or freezing, which can cause expensive repairs.

2. How Air Receivers Work

Tanks allow you to use air even when the compressor isn’t running and can also supply extra air to your production process during periods of high usage.

Air tanks can be manufactured to be either vertical or horizontal. Vertical tanks are more common because they take up less space on a shop floor, and who doesn’t like to have more space?

Because of the immense pressure vessels must contain, and because of how important they are in an air compressor system, air receiver tanks have to be built especially durable and strong.

Primary receiver tanks are located near the air compressor and act as a large storage reservoir that can be used during peak usage times.

Secondary containers can be used for end-use application or can provide general, additional storage at the end of a distribution line or loop. An addition of a second vessel can prevent dynamic pressure fluctuations which can affect the quality of your plant’s end product.

Most standard tanks are rated for use between 150 to 200 PSI, but if you need something able to handle more, don’t worry, 300 to 3000 PSI units are available for high-pressure applications. Receiver tank capacities can range from 10 to 10,000 gallons and can be sized by using the formulas listed below.

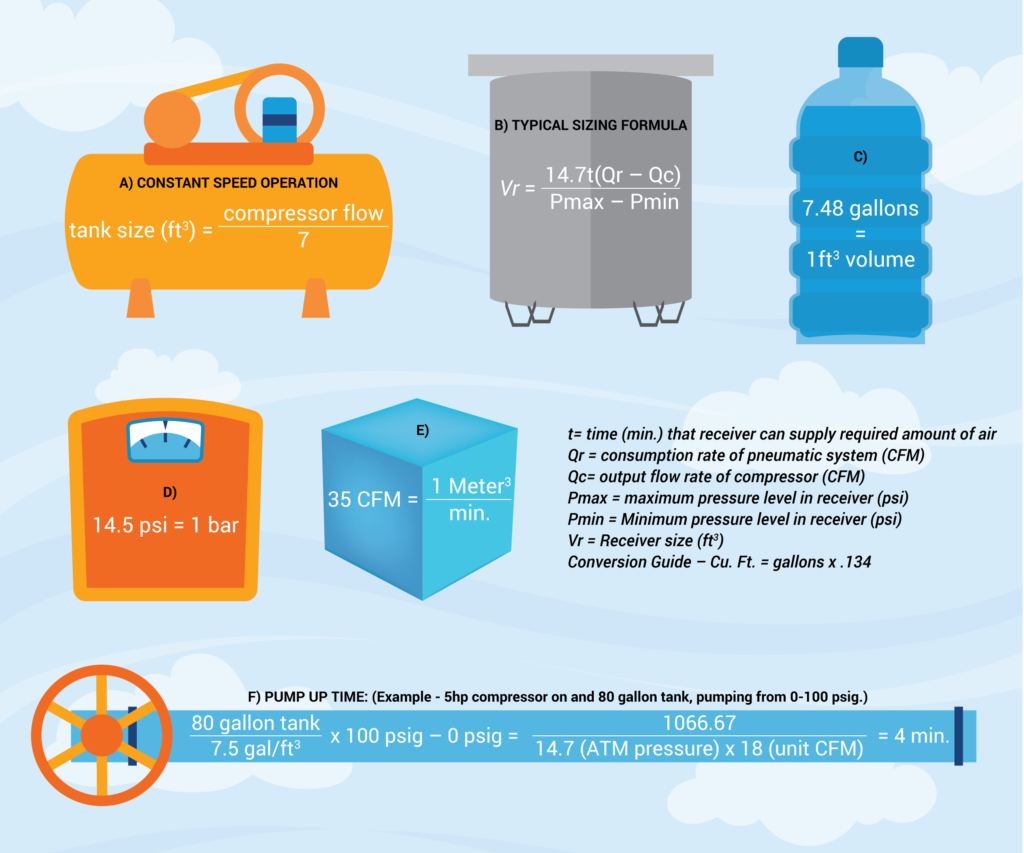

3. How to Properly Size Air Receiver Tanks

Factors To Consider:

Minimize Pressure Fluctuations or Drops

If you minimize pressure fluctuations you will get more control over the quality of your plant’s end product and how smoothly your production processes flow.

Take note of your compressor’s output pressure and what your application needs at the point of use. The compressed air in your vessel is only useful for your application if its pressure is high enough for the process that uses it.

This means that it is also important to consider the amount of time that the air receiver can supply air at the necessary pressure.

Meeting Short Term Peak Air Demands

For some production processes, the need for compressed air can change drastically throughout the day. It is important to consider the spikes in demand to be sure the system pressure doesn’t drop to below operating levels.

It is important to fully understand your application’s demands and the amount of CFM or liter/second of air required, as well as the expected peaks of your system because these are good indicators for how much flow of compressed air is needed so that you can avoid air shortages for any of your process.

Energy Considerations

Air receivers reduce energy consumption. By using the right sized tank and by having more air than what is required for your process, it will reduce the potential of the trim processor starting up to meet increased flow demand and working harder than it needs to.

Safety Considerations

If the situation arises, an air receiver can provide a supply of air to production systems and processes to enable a safe shutdown in an emergency situation. Hopefully, emergencies don’t happen but it’s always good to be prepared!

Air Receiver Tank Specification

A common rule of thumb is to have 4 gallons of storage per compressor HP (Horsepower) or to have 1 gallon for each ACFM (Actual Cubic Feet per Minute).

But to be more specific and to ensure that you are getting all of the benefits associated with the right sized vessel, plug your information into the equations below.

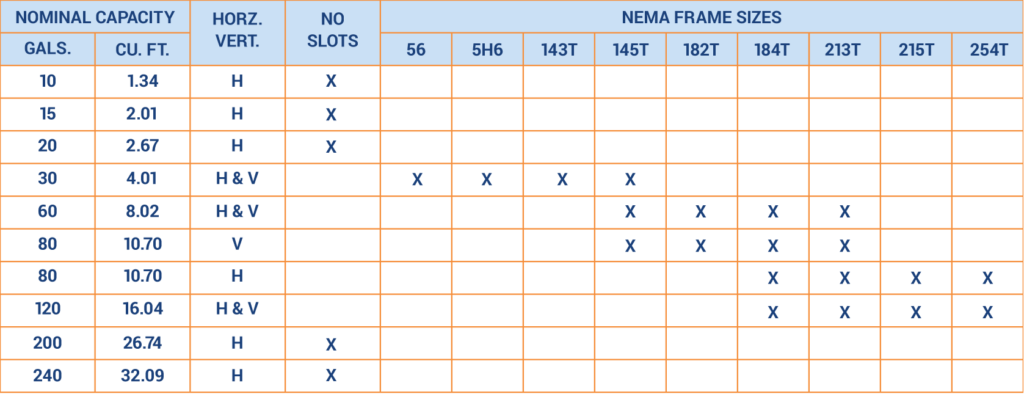

4. Products Offered by ISC Sales

ISC stocks standard models from 10 gallon to 10,000 gallon compressed air receiver tanks to accommodate most manufacturing needs and can ship from a regional warehouse within 48 hours after being ordered.

Features:

- Designed and constructed in accordance with ASME Section VIII Div-I Code for compressed air storage use.

- “U” stamped and registered with the National Board of Pressure Vessel Inspectors.

- Most designs include Canadian Registration Numbers (CRN).

- Capable of building to American Bureau of Shipping (ABS) and United States Coast Guard (USCG) codes.

- Custom engineered designs available upon request.

- Exterior surface painted with one coat standard shop primer.

- Special exterior and interior coatings available upon request.

Custom Options Available:

ISC Sales wants to meet the needs of all of our customers, which is why we also offer custom tanks. Whether you need a custom air receiver, nitrogen, oxygen or natural gas tank, our specialists will help you find the right fit for your application.

- An epoxy coating which makes an air tank resistant to corrosion. This is often used in harsh environments where the air has a large amount of moisture.

- Available in carbon steel, stainless steel and aluminum.

- Changing the location of inlet and outlet ports to suit existing equipment.

- Top plates to provide a flat surface at the top of a receiver tank.

- Safety valves which act as a fail-safe to release air out of the air tank if it exceeds capacity.

- Available in carbon steel, stainless steel, and aluminum and custom connections.

- ASME rated upon request

Air Compressor Sizing Chart

5. Additional Helpful Products

Compressed Air Safety Valves

Receiver tanks are required by law to have a pressure relief valve and a pressure gauge to maintain safety. The relief valve should be set to 10% higher than the working pressure of the system.

A safety valve (also called relief valve) is a valve mechanism for the automatic release of air from a pressure vessel when the pressure exceeds preset limits. They are UV stamped, factory set and sealed.

We offer a variety of options that can work for any application.

Our air safety valves are ASME regulated, National Board Certified Safety valves, Section I (V) and VIII (UV) rated for steam, air, gas and liquid applications.

The valves are interchangeable with all safety valve manufacturers and available with the full array of trimming and seating with many options.

All products go through rigid quality control. We set, test and re-test for each customized application prior to the code stamping process.

Still unsure of which air receiver tank will fit your needs?

Needs vary so much from application to application it is hard to determine what will work best.

But you’re in luck! The staff at ISC Sales is very knowledgeable, able to answer any of your questions and will ensure that you get the most efficient product for your business. Contact us today and have the air receiver tank that’s perfect for you tomorrow.

Call ISC Sales today at 972.694.4291 to get a free quote or to ask about our lineup of industrial equipment. You can also request a quote online, HERE.