Choosing the right air compressor or pump for your commercial or industrial facility can be challenging. Understanding the difference between the two will help you make the right choice for your company. Here are some important points to consider.

The Purpose of Air Compression

Both air compressors and pumps are used to move materials through a system. This capability is used in flood-control systems, hydraulic lifts, HVAC units, pneumatic tools and common appliances and industrial systems. Many of the activities of contractors and companies are made possible by the power of air pressure created by the right compressor or pump. Compressed air offers flexibility and safety benefits compared to alternative sources of energy, such as electricity. Air compressors and pumps are essential to the construction, agriculture, HVAC, energy and manufacturing industries.

Air Compressors vs. Pumps

As their name suggests, air compressors are designed to move gases and to compress them to change their temperature or to produce a more condensed gas. Pumps are more versatile and can move both liquids and gases. However, they do not usually put pressure on these materials. Instead, they simply propel the liquid, or gas, in a specific direction to convey it to the desired location. This is essential for irrigation systems, water treatment plants and other industrial applications where water or another fluid must be processed sequentially.

Air compressors, by contrast, can only move and compress gases. Pneumatic air tools used in construction applications are one of the most common examples of the practical use of air compressors. They are also used in motor vehicles of all types and in the energy industry. HVAC applications also use compressors to put pressure on refrigerant and to produce the cold air needed to keep interior spaces comfortable.

While pumps and air compressors may be sold separately, they are usually used together in the industrial environment. Combining industrial pumps and air compressors offer the greatest degree of control for agriculture, manufacturing and many other industries.

Two Primary Types of Industrial Pumps

Pumps are often used to remove water and other liquid materials from one area and transfer these liquids to another area. They can also transport gases and slurries, which consist of solids suspended in a liquid medium. Pumps are usually categorized by the mechanism used to move the liquid.

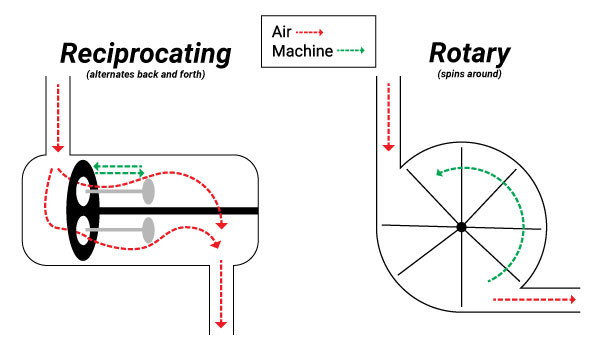

Reciprocating pumps use the principle of positive displacement to move water through a system of pipes. They are generally reserved for low-flow and high-pressure applications in the industrial environment.

Rotary pumps intake fluid and then press it out in a circular motion. These pumps are used most often to produce continuous flow with minimal pulsation, which makes them an ideal choice for many HVAC applications in the commercial and industrial marketplace.

Pumps are also divided into categories according to the way they move water or gas. Some of the most common types of pumps include gravity, direct lift, velocity and displacement pumps. Each of these types of pumps are used in the industrial environment to manage the flow of liquids and to promote the most efficient delivery of fluids to their desired destinations. In the industrial environment, compressor pumps offer the best of both worlds for end users. These advanced combination tools can propel and compress gases and fluids to provide end-to-end functionality for commercial and industrial concerns across the United States.

Industrial Air Compressors

Understanding the various types of industrial air compressors will ensure that you choose the right option for your company. Like industrial pumps, air compressors are generally divided into reciprocating and rotary varieties. Reciprocating compressors are the more efficient air compressor as they compress the same amount of gas with less energy input. This is important for industrial air systems whereas for home use it may not be as important.

Reciprocating compressor pumps are divided into one-stage and two-stage compressor types:

- One-stage compressors compress air only once before going into the tank. Keep in mind that one-stage compressor pumps can have multiple cylinders but they will be the same diameter. Cylinders with different diameters signify multi-stage compressor pumps

- Two-stage compressors compress air twice before going into the tank. A two-stage compressor pump typically has different cylinder diameters that are designed to increase or relieve pressure as the fluid or gas travels through the compressor. After the first compression, air cools in a heat exchanger tube and then compresses again before going into the tank. 2 stage air compressors are used in larger industrial applications and are suitable for continuous use. They are often used to power pneumatic tools with pressure readings over 100 psi in the normal course of operation.

Applications for Air Compressors

In general, one-stage air compressors are used in smaller applications that may include small-scale metalworking, carpentry and a wide range of repair and do-it-yourself activities. Multi-stage compressor pumps, i.e. either two-stage or three-stage compressor pumps, by contrast, are used in auto plants, beverage manufacturing facilities and aerospace applications. In industrial and commercial situations, two-stage compression is the starting point as it is necessary to maintain consistent power and force needed in larger-scale operations.

Industrial Air Compressor Options We Offer

ISC Sales offers an extensive lineup of industrial air compressor options that are designed to suit the needs of our customers across the United States. Some of the most practical and popular industrial compressors we distribute include models from these four categories:

Oil-Free Air Compressors

Oil-free air compressors feature pre-lubricated cylinders and Teflon coatings designed to allow them to run without constant oil lubrication. This can eliminate the need for regular oil changes and other maintenance tasks that can be time-consuming. Oil-free air compressors are also simpler in their design than oil-lubricated models, which usually results in a lower weight and easier handling in the industrial environment. Available in both one-stage and two-stage models, oil-free air compressors are often used in medical, dental and laboratory environments to provide a cleaner and contaminant-free solution for these applications.

Reciprocating Air Compressors

Reciprocating air compressors are also referred to as piston air compressors because they use a piston-like motion to build up pressure on air. These units typically have a high compression efficiency and are ideally suited for use in home workshops, auto repair shops and in construction sites to power nailers and other pneumatic tools.

Rotary-Screw Air Compressors

Rotary-screw air compressors are designed to compress air between two interlocking and rotating rotors. This innovative design allows them to run continuously, which can significantly improve productivity and can reduce maintenance requirements to a significant degree. Rotary-screw compressors are best suited for commercial and industrial environments where continuous operation and high-pressure air is required.

Air Compressor Pumps

Air compressor pumps deliver compressed air where it is needed most. These pumps are designed to work with a range of compressor types and to provide the necessary power for pneumatic tools, HVAC systems and many other elements necessary in the industrial and commercial fields.

At ISC Sales, we take pride in delivering the best air compressor options and in providing the most accurate information and guidance for our customers. Our Product Specialists have the knowledge and the proven experience needed to recommend the solution that is right for your needs.

Our Commitment to You

ISC Sales has been in business for over 30 years, offering the best customer service. We offer a comprehensive lineup of air compressors and pumps designed to supply you with the right pneumatic tool. To learn more about our suite of compressed air products and components and to allow us to provide a customized recommendation, give us a call today at (877) 602-0010. Our team of customer service specialists are here to serve you now and in the future.