Explosions and fires can occur on industrial and manufacturing properties, causing equipment damage, employee injury, and property harm.

According to the National Fire Protection Association (NFPA), an average of 37,000 fires occur at industrial and manufacturing properties yearly.

These incidences resulted in:

18 civilian deaths |

279 civilian injuries |

$1 billion in direct |

*NFPA’s findings do not consider the number of profits lost due to downtime.

To better protect your teams and investments, it is crucial to be aware of the risks associated with industrial processes.

The Occupational Safety and Health Administration (OSHA) defines a hazardous location as:

“Hazardous locations are areas where flammable liquids, gases or vapors or combustible dust exist in sufficient quantities to produce an explosion or fire. In hazardous locations, specially designed equipment and special installation techniques must be used to protect against the explosive and flammable potential of these substances.” Publication 3073

An industrial building with ignitable gases, flammable liquids, combustible dust, or ignitable fibers becomes a risk only when significant amounts of hazardous substances are present.

What Happens When an Enclosure Explodes?

An explosion is defined as a violent expansion in which energy is transmitted outwards as a shock wave. We have all seen big, dramatic explosions in our favorite action films, and while exciting on the big screen, explosions are disastrous in real life.

Explosions are most likely to occur in chemical plants, refineries, paint shops, cleaning facilities, mills, flour silos, tanks, and loading facilities for flammable gases, liquids, and solids.

Factors That Cause Explosions

All three sides of the triangle must be present for an explosion to occur, starting with a tiny, little spark.

1. Flammable Substance (Fuel)

There must be enough flammable substance to produce an ignitable or explosive mixture that could create an explosion or fire. In addition, a fire must have fuel to burn.

2. Oxidizer (Air)

An oxidizer is a type of chemical which a fuel requires to burn. Therefore, enough of an oxidizer must be present to cause an explosion, like oxygen.

3. Source of Ignition (Heat)

A spark or high heat must be present. A fire does not start without a source to light or heat it high enough to cause the material to combust on its own.

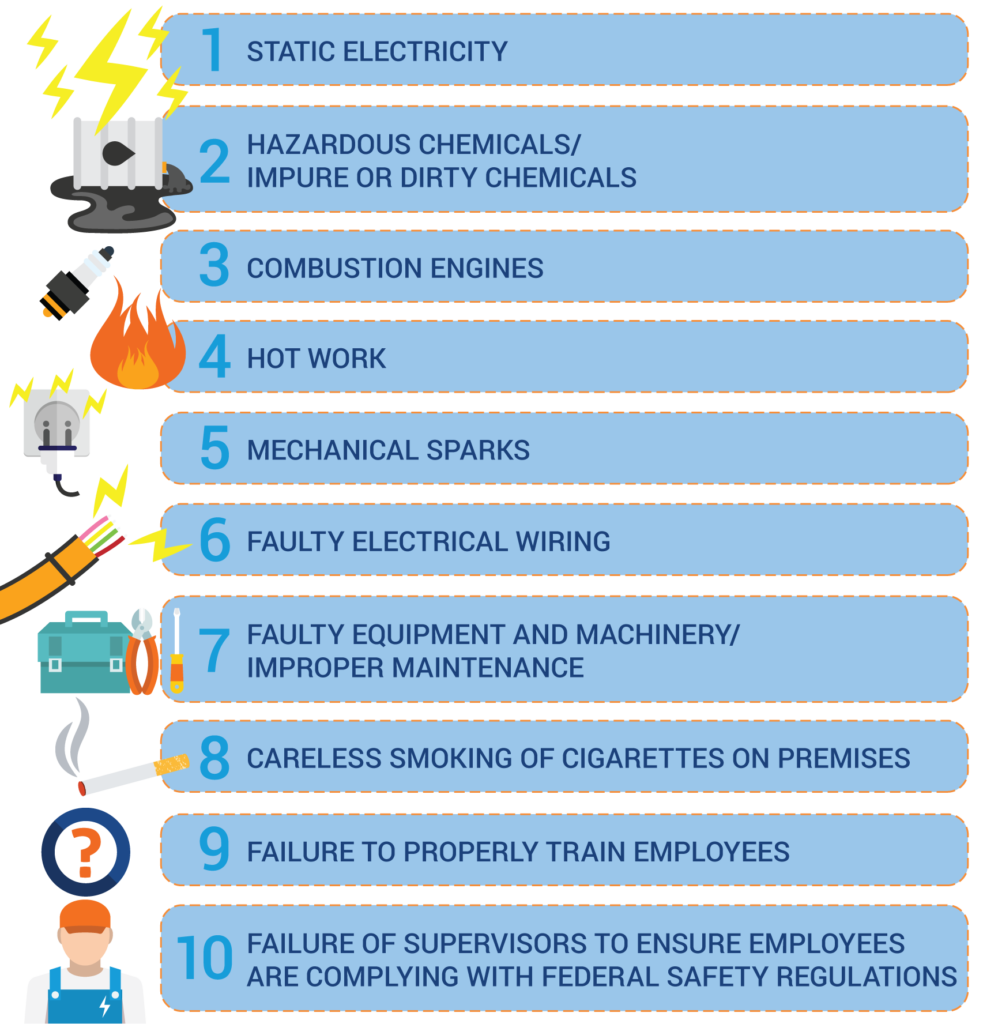

Major Causes of Industrial Fires and Explosions

Defining the Risks

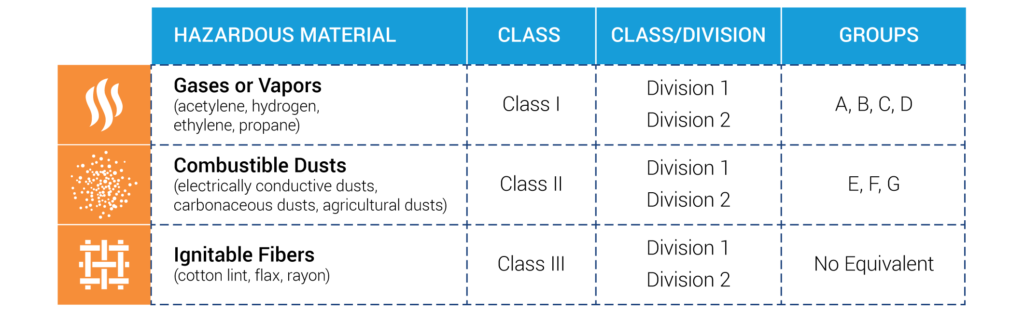

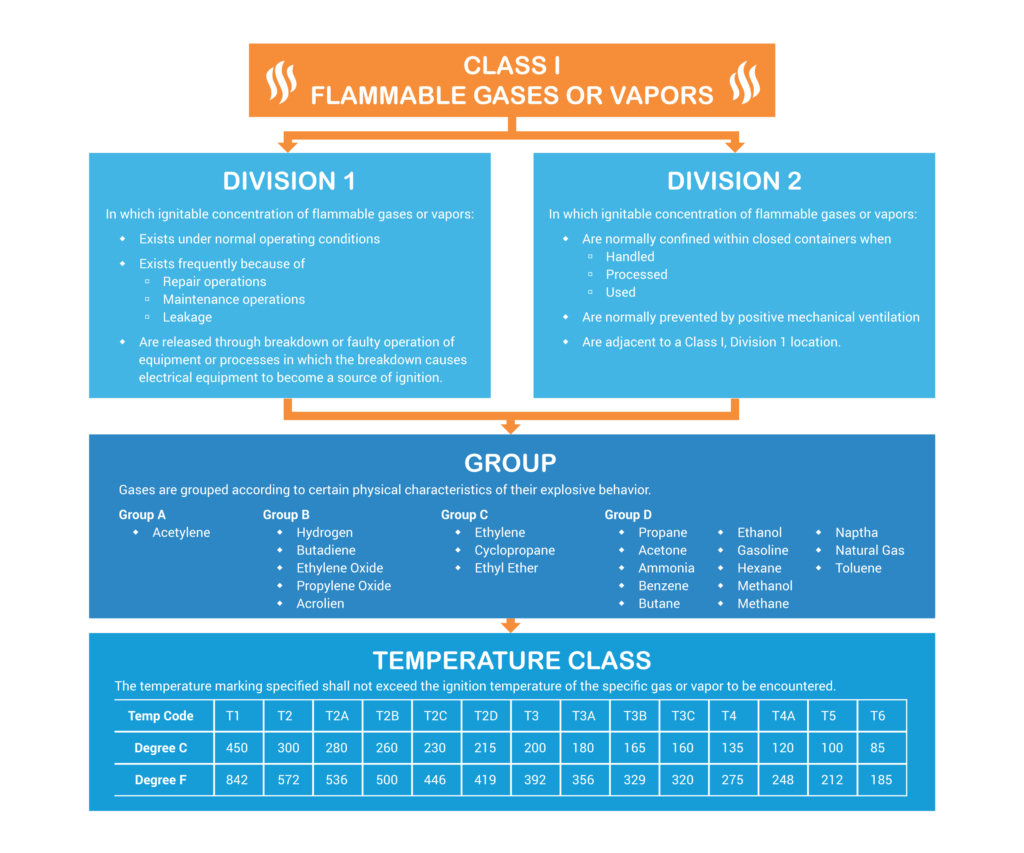

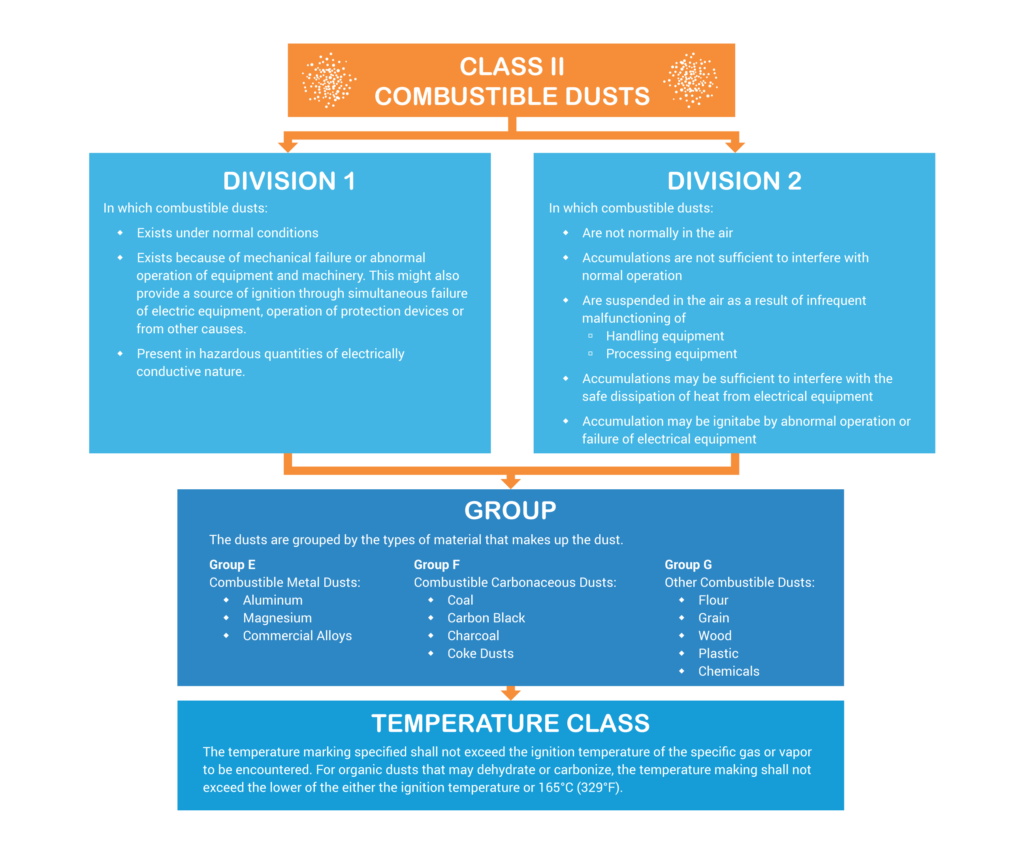

The National Fire Protection Association (NFPA) publishes the National Electric Code (NEC) 70, which defines hazardous locations through a system of classes, divisions, and groups that enclosures and other equipment must be labeled for use in those areas. Hazardous area classifications are based on the type of substance or material present in the area, the likelihood that it exists, and more detailed specifics, such as ignition temperatures and explosive properties.

Classes

Classes state the type of ignitable substances present that could potentially start fires or cause an explosion.

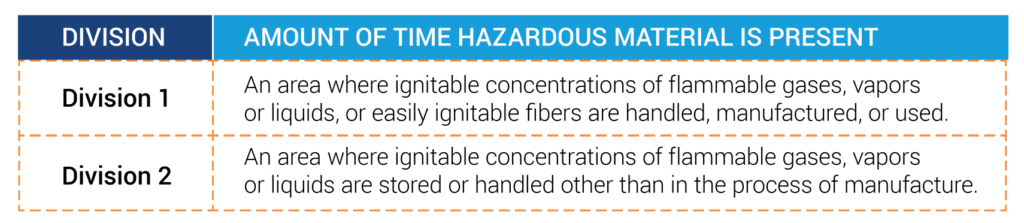

Divisions

Divisions define the amount of time a hazardous material is present during production processes.

Groups

Groups specify materials based on ignition temperatures and explosive materials.

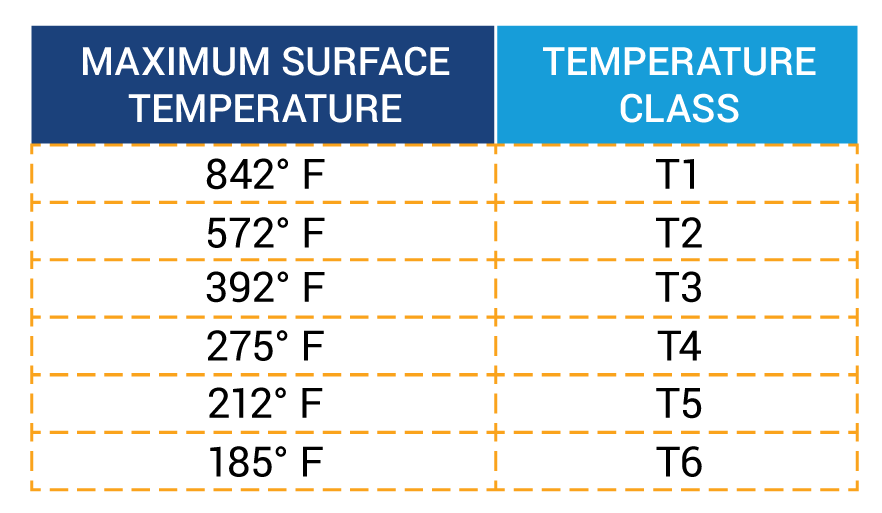

Temperature Class

Temperature Class tells the minimum temperature that substances will ignite because of high heat. The temperature at which substances explode or begin to burn with no igniter like a spark or flame.

Pay Attention To the Class

Class I: Gases Or Vapors

Class I locations have large amounts of flammable gases or vapors present, which could cause an explosion. Common examples of combustible gases and vapors are hydrogen, methane, and gasoline.

Typical Class I locations include airplane hangars, vehicle paint shops, commercial laundromats, and gas plants.

Class II: Combustible Dusts

Combustible dust is a solid material composed of fine particles or pieces, regardless of their size, shape, or chemical composition. It becomes a fire hazard when suspended in air or another oxidizing medium. If dust is suspended in the air with the right concentration, it can become explosive. Some materials that are not usually flammable can become explosive as dust, like aluminum or iron.

Granaries, mines, sugar or starch plants, and plastic-producing factories are typically considered to be Class II locations.

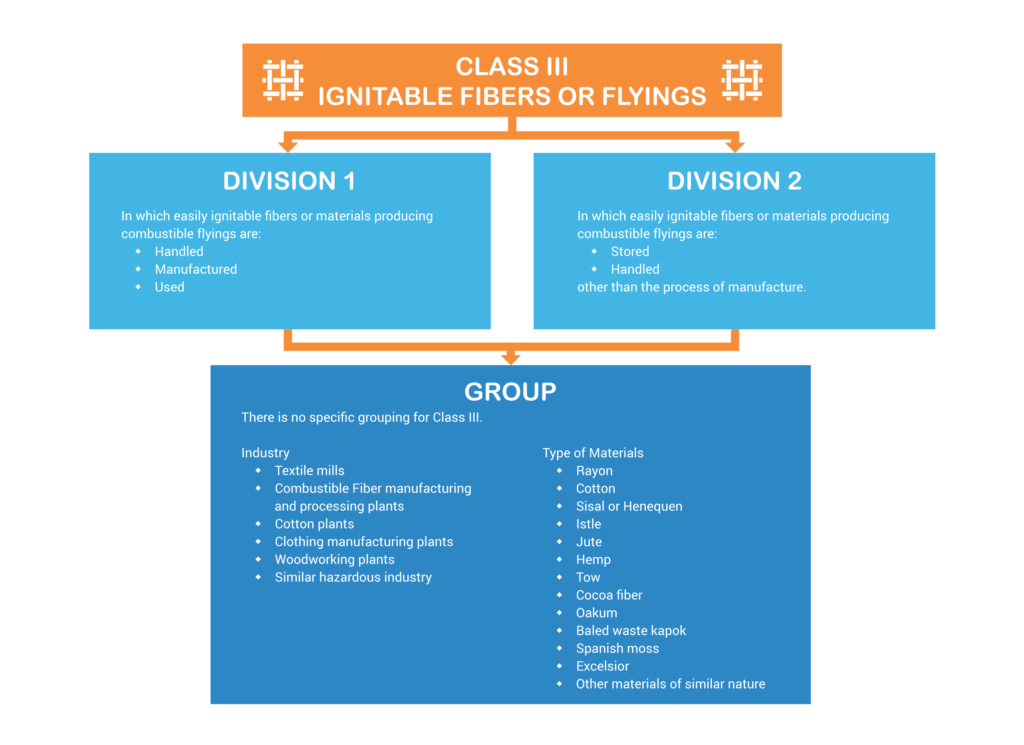

Class III: Ignitable Fibers

Ignitable fibers are a severe fire risk. Materials, such as cotton, flax, or rayon lint, can form highly flammable a layer throughout a facility and, if it were to be ignited, will cause a flash fire. Flash fires move quickly, at near-explosive speeds.

Typical Class III locations include textile mills, cotton mills, and sawmill facilities.

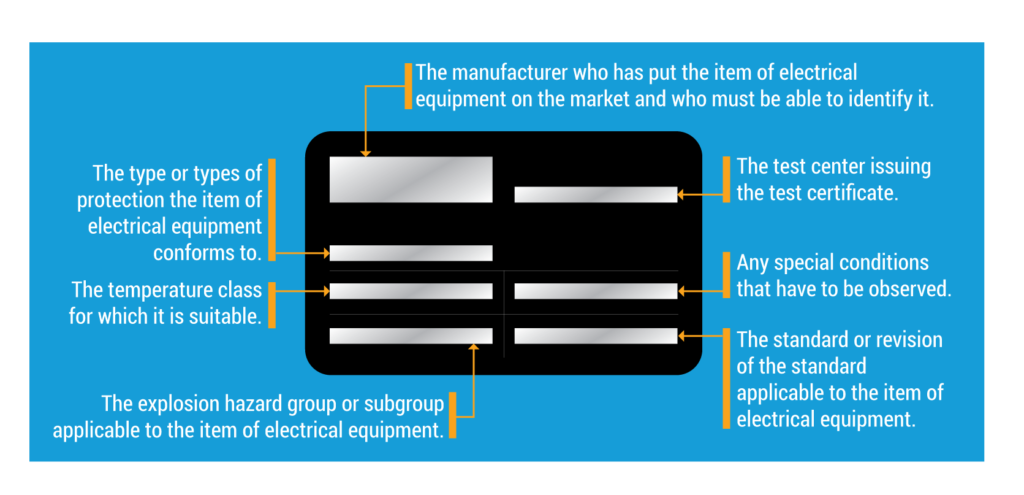

What Are Those Markings On the Nameplate?

Explosions and fires can be prevented by using the correct equipment. Electrical enclosures are rated and marked so consumers can make educated decisions while selecting components.

The marking must indicate:

- The manufacturer

- The type or types of protection the enclosure provides

- The temperature class for which it is suitable

- The explosion hazard group or subgroup

- The test center issuing the test certificate

- Any special conditions that must be observed

- The standard or revision of the standard

What Does a UL Certification Mean?

Underwriter Laboratories, LLC (UL) is a global safety consulting and certification company. To be UL rated means that a product has met nationally recognized safety standards and is safe for use in specific environments for which it is certified.

How To Prevent Explosions Caused By Electrical Equipment

Remember the fire triangle? By limiting or inhibiting the three sides of the triangle, you can significantly lower the risk for explosions and fires.

1. Confine the Explosion

The National Electrical Manufacturers Association (NEMA) is an ANSI-accredited Standards Developing Organization consisting of business leaders, electrical experts, engineers, scientists, and technicians, and defines standards used in North America for various grades of electrical enclosures usually used in industrial applications. Each is rated to protect against specific environmental conditions. For example, a typical NEMA enclosure might be rated to protect against environmental hazards, such as water, dust, oil, coolant, acetylene, or gasoline.

By enclosing equipment, you remove the ignition side of the triangle. An explosion or fire is less likely to occur if hazardous materials do not come into contact with equipment, which can generate a spark or high heat.

Examples:

- Explosion-proof enclosures

- Dust ignition-proof enclosures

- Conduit and cable seals

2. Limit the Energy

Various methods can be used to limit or eliminate available energy, both electrical and thermal. Without power, another piece of the fire triangle is missing and an explosion cannot occur.

Examples:

- Intrinsic safety

- Pneumatics

- Fiber optics

3. Isolate the Hazard

Isolating the hazard prevents or delays the diffusion or spreading of a hazardous substance into an enclosure where a possible ignition could occur. Without a material to feed the fire, you eliminate a side of the triangle, preventing an explosion or fire.

Examples:

- Pressurization and purging

- Oil immersion

- Hermetic sealing

- Encapsulation (potting)

- Restricted breathing

Hazardous Location Additions for Enclosures

Hazardous Location Enclosure Coolers

Hazardous Location (HazLoc) Duty Vortex AC Coolers are explicitly designed for purged electrical enclosures in Class I Div 2 Groups A, B, C, and D; Class II Div 2, Groups F and G; and Class III locations.

When the unit’s integrated mechanical thermostat senses acceptable enclosure temperatures, the purge system creates positive pressure in the enclosure. This occurs as the HazLoc Vortex AC’s integrated check valve seals off the cold air outlet, allowing the purge system to maintain the necessary pressure to block gases, vapors, dust, fibers, and other contaminants from entering the enclosure.

The HazLoc Vortex AC is specifically designed for simple installation and flexible mounting. The check valve’s design does not limit its mounting position or cold air ducting.

Benefits of HazLoc Vortex AC Coolers:

- No maintenance required

- Effortless and quick top or side mount installation, with no wiring, no electricity

- Extremely reliable

- Very quiet

- Integrated mechanical thermostat maintains 80-90°F temperatures

- Operates in environments up to 175°F

- Requires a purge and pressurization system

Hazardous Location Air Conditioners

Hazardous Location Air Conditioners are designed to cool the internal environment of hazardous location enclosures that contain electrical equipment and ideal for use on process control systems in chemical, petrochemical, refining, and field and offshore drilling applications.

These Hazardous Duty enclosure air conditioners are rated for use with purged and non-purged enclosures located in Class 1, Div II, Groups A, B, C, and D hazardous environments.

Benefits of HazLoc AC:

- Easy maintenance

- Programmable digital controller with built-in alarms and remotes

- For purged and non-purged enclosures

- Equipped with a Condensate Evaporation System

- Thermal Expansion Valve for maximum efficiency when temperature or heat load changes

Purge and Pressurization Systems

Purging is the process of supplying an enclosure with compressed air (or inert gas) at the proper flow and pressure to reduce the hazardous gas inside the enclosure to a safe level. Pressurization is the process of increasing the air pressure within an enclosure to the point where there is no ingress of hazardous or combustible gases.

Type X

Type X purging and pressurization systems reduce the classification within the protected enclosures from Division 1 to non-hazardous. In addition, these purge systems are fully automatic and perform critical purging, pressurization, and monitoring of an enclosure in a single dependable unit, eliminating operation guesswork and increasing system effectiveness.

Type X systems operate by forcing air (or inert gas) through the enclosure for a specified time until all the hazardous gas is removed, creating a positive pressure maintained by either a continuous or compensating airflow through the enclosure.

Type Y

Type Y purging and pressurization systems regulate and monitor the pressure inside sealed enclosures to prevent flammable vapor from contaminating the enclosure.

The Type Y system is designed to reduce the classification within a protected enclosure from Division 1 to Division 2, allowing Division 2 rated equipment to be operated in Division 1 locations.

Type Z

Type Z purging and pressurization systems are rapid exchange purging systems that operate on a supply of compressed air (or inert gas). It regulates and monitors pressure within one or more sealed enclosures and rapidly removes and prevents flammable vapor accumulation within the enclosure.

It is rated for Class I, Division 1 to Division 2 area applications or Class II, Division 1 to Division 2 applications.

Do You Need a HazLoc Enclosure?

Needs vary so much from application to application; it is hard to determine what will work best. Check out our new Hazardous Location category for all HazLoc enclosures and accessories!

You can also speak with our knowledgeable staff at ISC Sales. We will be able to answer any of your questions and ensure that you get the most efficient product for your business. Contact us today and have the hazardous location equipment perfect for you ASAP.

Call ISC Sales today at 877.602.0010 to get a free quote or to ask about our lineup of industrial equipment. You can also request a quote online, HERE.