We have all come to rely heavily on HVAC (heating ventilation and air conditioning) and air conditioning (AC) technology to keep things running coolly. In fact, we have grown so accustomed to being in cool and comfortable environments that scientists have proven that we have lost some of our natural tolerance to handle high temperatures.

The impact made by the creation of AC can be found across all platforms and industries. Modern air conditioning has:

Allowed for huge advancements in medical technology |

Led to an increase in human life expectancy |

Effectively lowered the rate of how quickly diseases can spread |

No matter what your job is or where you work, AC has increased employee productivity. This is no surprise because when you’re not sweating and miserable it makes it much easier to work and concentrate!

There are many components responsible for keeping ACs running to provide our home, offices, places we shop and visit at comfortable temperatures, but the most important component of the equipment is the compressor.

What Do HVAC Compressors Do?

If we were looking at HVAC systems like they were a living, breathing thing, the compressor would be the heart of the unit. Without a heart nothing could live, the compressor is the most important component of the air conditioning system and without it, your AC unit cannot do its job.

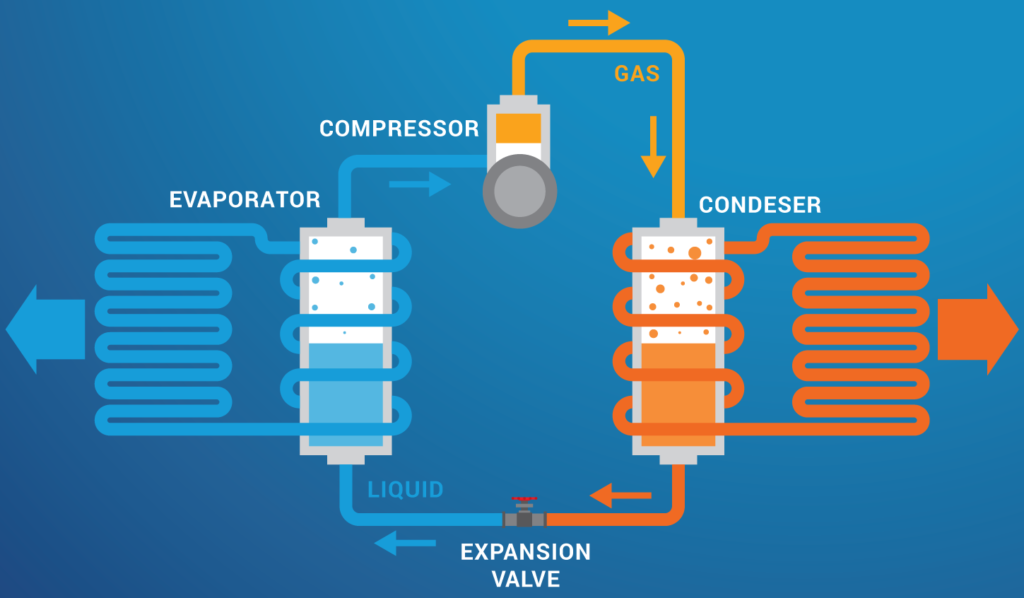

Compressors are the mechanical components that cause the refrigerant to flow in a cycle, much like the way the heart pumps blood throughout your body. Just like the name states, this machine compresses the refrigerant gas and pumps it through the system so it can remove heat and humidity from the air.

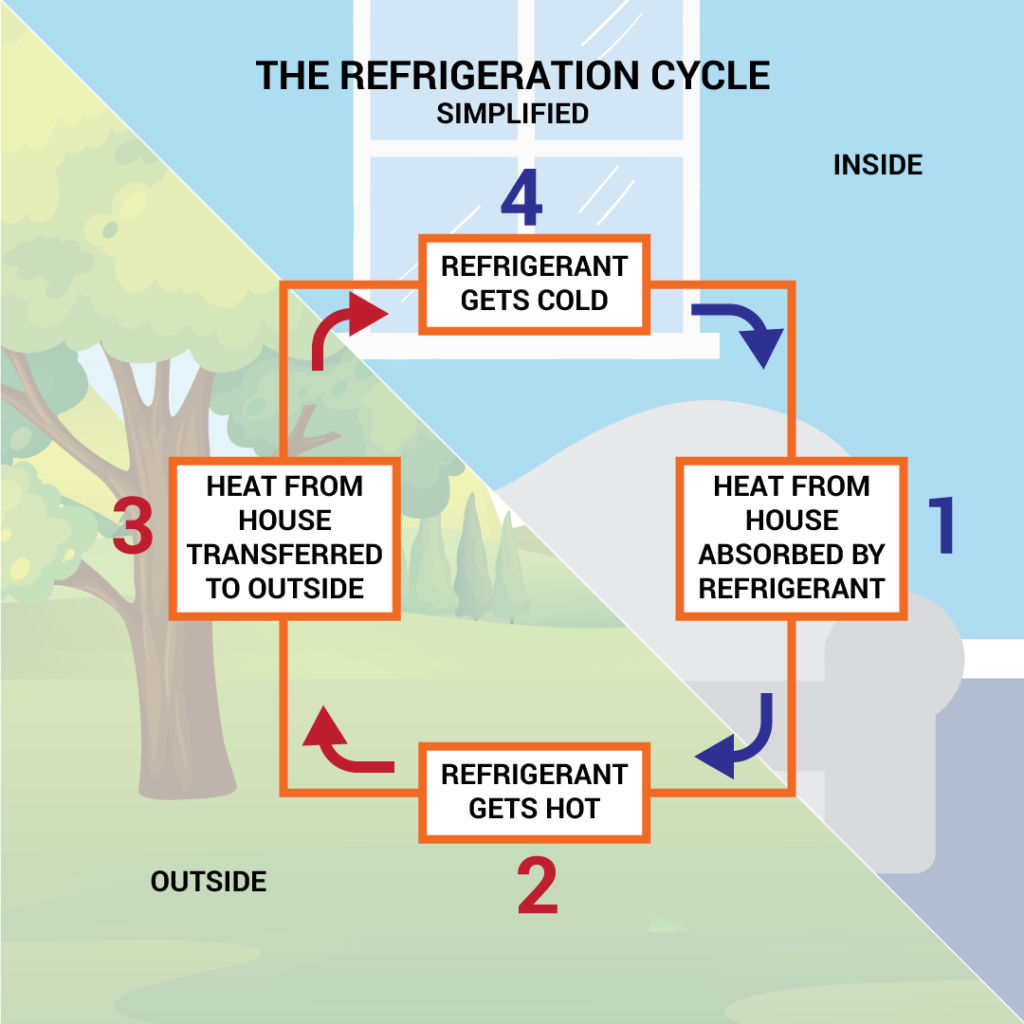

HVAC systems pull heat out of the air, and then cool it over a set of cold pipes, also called evaporator coils. It then releases the cold air into your office, building or home. The evaporator coil can remain frigid thanks to liquid refrigerant which is what absorbs the hot air and changes it into gas. The gas is then moved outside to the condenser coil where it changes back into a liquid and then the whole cycle is repeated.

The compressor is what moves the refrigerant between the evaporator and the condenser coils which is what makes sure the refrigerant changes from a gas to a liquid as it is needed.

Compressors are generally very reliable and have a lifespan of 10 to 15 years before they fail and just like your heart, you don’t think about how much work it does until it stops working well. If you eat healthily and exercise your chances of heart problems are decreased. And with proper maintenance and care the chances of your compressor failing will be significantly less as well.

The most common causes of both heart problems and compressor failure are often from a preventable underlying problem, so be sure to do the things that will help keep the compressor running smoothly. If the compressor does happen to fail, it’s detrimental to the whole system and is either very expensive or impossible to fix.

5 Important Things To Remember About HVAC Compressors

1. Where Will the Compressor Be Located?

Is your compressor going to be near employees where it needs to be quiet during working hours? Is the compressor in a hot environment where it is susceptible to over-heat? The environment where your compressor will be housed can impact which compressor will work best for your application or how to best maintain your equipment.

2. What Type of Compressor Do I Need?

In order to take care of your system properly, you have to know how your system works. While all compressors do the essentially same thing, the way in which they do it varies from compressor type to compressor type. Scroll compressors have different parts and work differently than piston compressors. Knowing which compressor you need and how it works will make it easier to troubleshoot issues and will dictate how you maintain your ac unit.

3. How to Take Care of the Compressor?

By maintaining the other elements contained in your HVAC system you can effectively extend both the life of your compressor and the other components contained in your system.

- Wrap the compressor:

During cold winter months, when the compressor is not in use it is important to protect it from cold weather. Be sure that the power source is disconnected while you wrap a clean cloth around it for safety. - Remove any obstructions:

Remove anything that could prevent air flow. If there is not an appropriate amount of airflow the compressor and other components can wear out prematurely due to overworking. - Clean the air filter regularly:

This is another way to help promote air flow. Without dust and dirt clogging your filter, the compressor and other elements of your HVAC system will work better and longer without problems. - Clean the condenser coil regularly:

Every two weeks clean the condenser coil with a blower. Clean condenser coils allow the compressor to work at its most efficient while it cools. This is also a good time to check the compressor for any refrigerant leaks.

4. What to Do If the Compressor Stops Working?

There are three common signs that your compressor is not functioning properly, which are easily identifiable.

- Noises coming from the unit:

Banging or clanking noises indicate that there is most likely a part is loose inside the compressor. Bubbling or hissing can mean that there is a leak in the refrigerant. If you hear a brief noise during startup, don’t worry, this is normal. The only time to worry is if the noise is constant or if it differs from the usual sounds you’re used to hearing. - It’s too warm:

This could mean that the compressor is loose or worn out. With either of these situations, the air conditioner can’t cool properly and will need to be repaired or replaced. - Hard starting:

Hard starting means that the compressor is struggling to turn on or off. This problem could be the result of an electrical problem, like a faulty switch or wire.

These are not the only problems that can occur with compressors, they are just the most common. Other issues include the outdoor unit is running hot, the compressor has burned out or the air conditioner system isn’t working at all. These problems could stem from the compressor or could be a consequence of another component malfunctioning.

5. How to Fix A Compressor?

Fixing the problems associated with your HVAC system can be tricky. It is advisable that you contact an HVAC technician to ensure that you can quickly and effectively fix your system to get it back to cooling your space as soon as possible.

Compressors Offered by ISC Sales

RECIPROCATING or PISTON COMPRESSOR

The reciprocating compressor utilizes pistons to compress the refrigerant. It is driven by a crankshaft in a straight line with a back and forth motion. This rotary motion is achieved by the use of an electric motor and the construction is similar to automobile engines.

As the piston moves up and down inside the cylinder, it moves vapor from the suction line through to the intake valve as the piston moves downward. As the piston begins to move upward, it compresses the vapor refrigerant, which then pushes it through the exhaust valve into the condenser.

+ Triple duty compressors that may be used in low, medium and high-temperature applications

+ Direct replacement compressors for Whirlpool, GE and Electrolux appliances

+ Replacement compressors for food service equipment, vending machines, bottle coolers, ice machines and other refrigeration equipment

+ Less expensive than other compressors

+ Easy maintenance

+ Suitable for high pressures

– Very noisy

– High outlet temperature of compressed air

– High oil content in air piping

– Lower flow rates

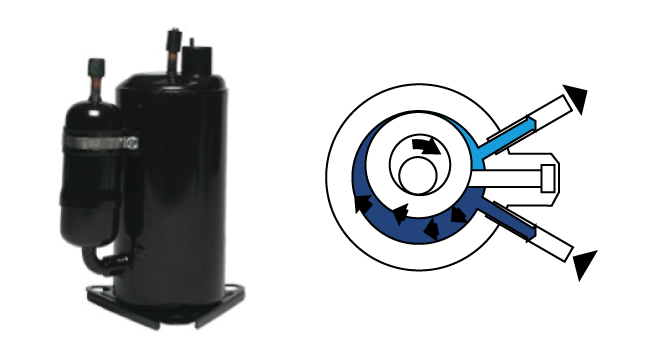

SCROLL COMPRESSOR

A scroll compressor has one fixed scroll which remains stationary and another moving scroll that rotates with the use of swing link. As the rotation occurs, the refrigerant between the two scrolls is slowly pushed to the center, causing the reduction of the volume of the gas. It is then discharged through the center port to the condenser.

The scroll compressor is also known as scroll pump or scroll vacuum pump.

+ Fewer moving parts and less torque variation compared to piston compressors

+ The lack of pistons allows the compressors to reach 100% volumetric efficiency, leading to reduced energy costs

+ Smooth and quiet operation

+ Compact design

+ Smaller environmental footprint

– Cannot be disassembled for maintenance

– Can only rotate in one direction

PANASONIC ROTARY COMPRESSOR

Panasonic rotary compressors use vane pump technology. Its parts consist of a rotor, stator, and eight rotating blades, or vanes. As the rotor spins the vanes, they are forced outwards from their slots and are held against the stator walls by centrifugal force. This process builds pressure and is what creates the air compression.

ISC Sales is proud to be the only certified distributor of Panasonic compressors in North America, being a well-known and respected brand with a reputation for quality and long life.

+ Simple maintenance, long lifespan

+ Simpler structure, fewer components, larger capacity, and high efficiency

+ Lightweight with compact design runs smoothly with limited vibrations

+ Quiet operation generating less noise than other compressor options

+ Perfect for large or industrial applications

– Impractical to design for a capacity below 20 tons (70 kW), due to the rotor processing technology

Still unsure of which HVAC Compressor will fit your needs?

Needs vary so much from application to application it is hard to determine what will work best.

But you’re in luck! The staff at ISC Sales is very knowledgeable, able to answer any of your questions and will ensure that you get the most efficient product for your business. Contact us today and have the personal air conditioning equipment that’s perfect for you tomorrow.

Call ISC Sales today at 972.694.4291 to get a free quote or to ask about our lineup of industrial equipment. You can also request a quote online, HERE.